Reverse engineering/scanning

Reverse engineering/scanning

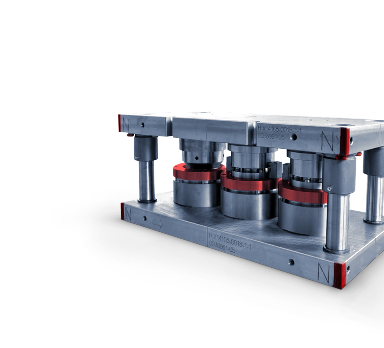

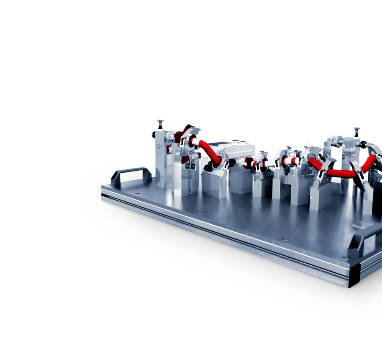

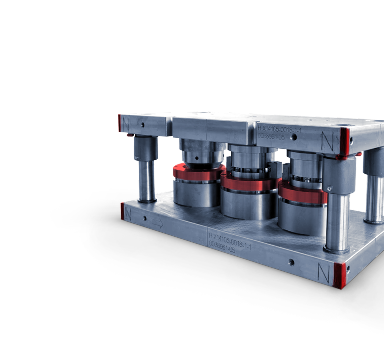

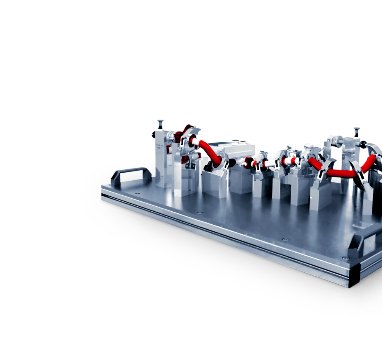

You have in your possession the product you want to produce and we know how to create production documentation for it thanks to our technologies. Although we don’t have a time machine to go back with you and see how it was made – with a 3D scan we can retrospectively produce documentation for the production of individual parts and entire assemblies.

How does it work?

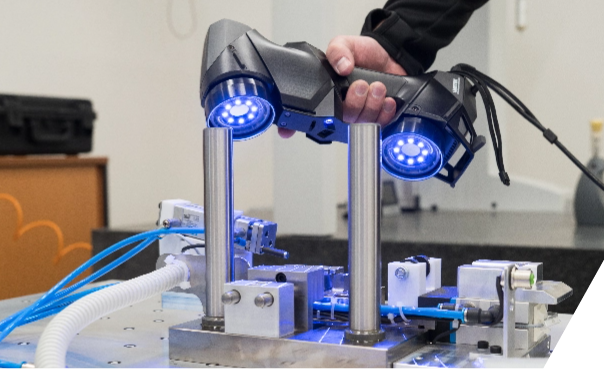

With 3D scanning, we digitise physical pieces with high accuracy. We scan using a touch scanner (a 3D coordinate machine) and a non-touch scanner (optical scanner). This allows us to perform detailed analyses of existing components or systems and find ways to improve them. Using reverse engineering and scanning, we’re able to respond quickly to changing market demands, deliver innovative solutions, or create production documentation for individual parts and assemblies.

What Machines Do We Use?

| Machine | Max. dimensions (travel) X/Y/Z [mm] | Accuracy [um] |

|---|---|---|

| Coordinate measuring machine Hexagon GLOBAL Classic 09.15.08 | 900/1,500/800 | 2.2 + L [mm]/300 |

| HandySCAN BLACK|ELITE optical scanner | 50–4,000 mm for all axes | 20 + 40/m |

| Keyence IM-7030 profile projector | 300/200/75 | 8 + 0.02 L [mm] |

What can we do to help?

Over 30 years of experience gives us the confidence and you the assurance that we’ll find the best solution. We’ll do our best to ensure that at the end of the cooperation you take home the perfect product, tuned to the last detail, and also a grin from ear to ear. Just tell us your idea and we’ll take care of everything else.