Pressing

Pressing

You have a clear vision of what you want to produce and we have everything else to supply millions of stamped parts a year. In our press shop, which still smells brand new, we can produce anything you want.

How does it work?

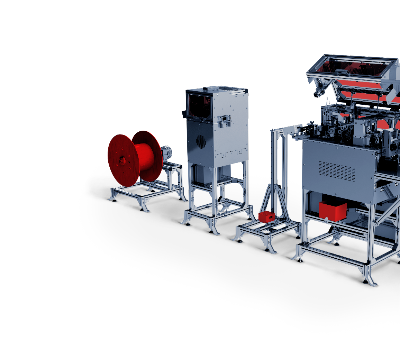

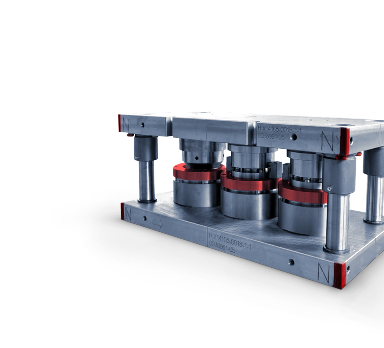

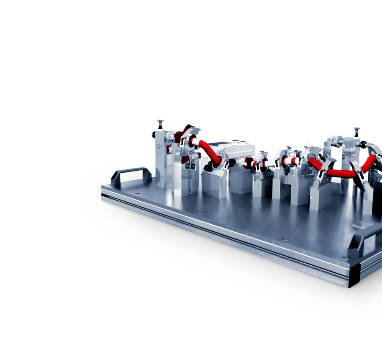

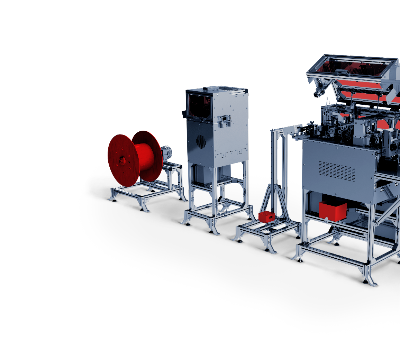

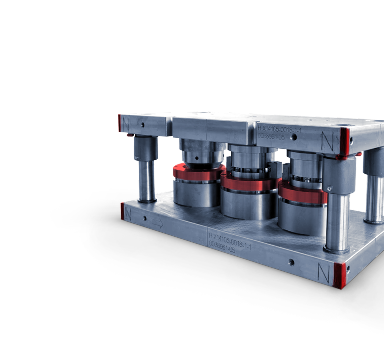

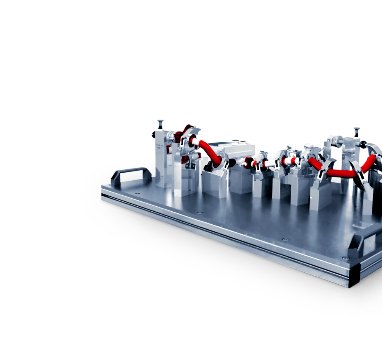

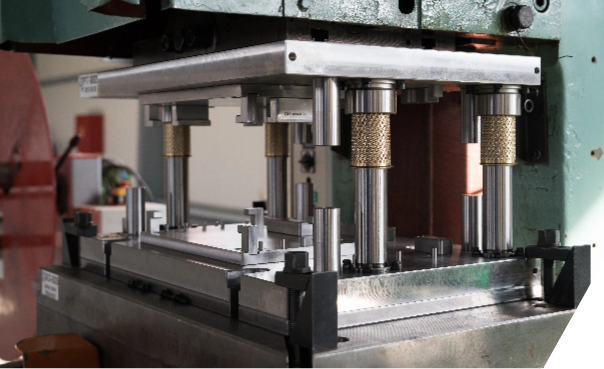

In 2023 we expanded our premises to include a modern press shop. On 1,100 m2 we have hydraulic and mechanical presses that we use to tune the tools we produce. And we can provide complete serial production without a problem. We can produce a wide range of products – from automotive parts to electronics – and if necessary, we can easily create for you a custom tool.

And we don’t stop there. We also do prototype pressing. So if you need fewer mouldings, you’ve come to the right place. We use simpler tools to produce them and we can even produce just individual units.

Our machine assemblage also includes the mechanical presses PEE III 160, LDC 160, LEXN 100C, LEN 63P, LEN 40C and LENR 25A, as well as the hydraulic press LAGAN 135 - DL. We use them to provide you with the fast delivery of mouldings for mass production – exactly according to your wishes.

What can we do to help?

Over 30 years of experience gives us the confidence and you the assurance that we’ll find the best solution. We’ll do our best to ensure that at the end of the cooperation you take home the perfect product, tuned to the last detail, and also a grin from ear to ear. Just tell us your idea and we’ll take care of everything else.