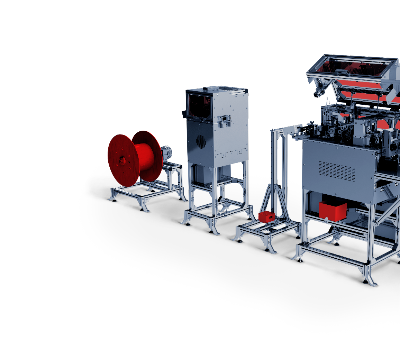

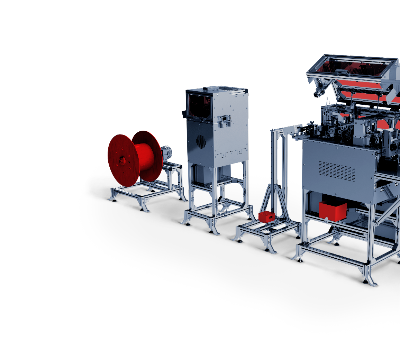

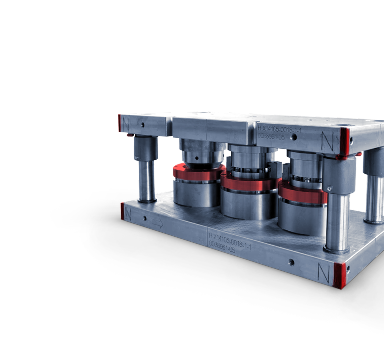

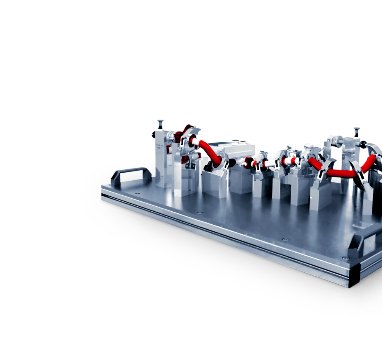

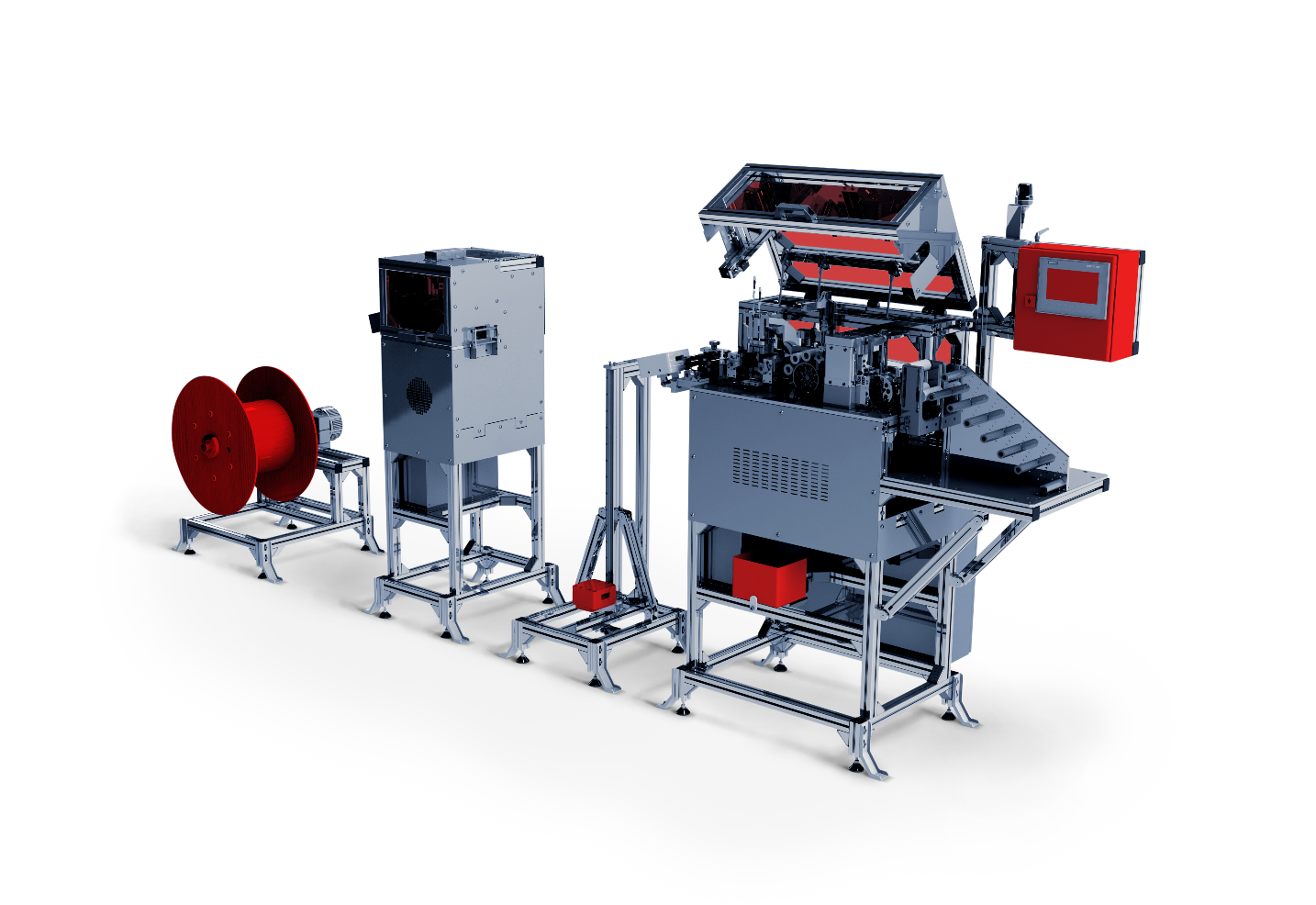

Single-purpose machines

Single-purpose machines may not be masters at doing multiple things at the same time – but they handle a specific task so well that they can easily beat the greatest masters in the field. Our experts tune them to perfection to perform their task quickly, efficiently, and with maximum precision. This saves you time and a lot of unnecessary production steps. And the result? Increased productivity, minimised errors, and maximum utilisation of your production capacity.

Single-purpose machines may not be masters at doing multiple things at the same time – but they handle a specific task so well that they can easily beat the greatest masters in the field. Our experts tune them to perfection to perform their task quickly, efficiently, and with maximum precision. This saves you time and a lot of unnecessary production steps. And the result? Increased productivity, minimised errors, and maximum utilisation of your production capacity.

Single-purpose machines play a key role in a number of industries. They have found their place in the manufacturing, electronics, and automotive industries. Wherever you need consistent and efficient material processing in one specific task you’ll find them at your fingertips. Every single-purpose machine is original and we can create it exactly according to your requirements.

We supply products for many industries

Automotive Industry

Electrical Industry

Construction Industry

Processing Industry

Production Process

We define your needs

Every single-purpose machine is different, but they have one thing in common. We can make them 100% according to the customer’s wishes. Together we’ll review the machine’s required functions, specify the type of drive and control system, and determine the final price accordingly.

Creating a proposal

Our seasoned designers take great care to give ideas a clear outline and they transfer the overall design and construction of the machine into a specific design. Together with the project manager, they will provide all the necessary parts and prepare the documents for subsequent processes with the greatest care.

Starting production

The drawing documentation travels a few doors down, where experienced technologists take charge. They determine the optimal technological process for the production of individual components. Then they pass the baton to production staff, who turn the design into real-life perfect parts thanks to proven technologies.

Checking everything carefully

The parts are then made, and that means they all come together for a inspection measurement by the metrologist. The metrologist thoroughly verifies their quality, and if everything is in order we can go ahead and assemble.

Building the machine

A toolmaker enters the scene to assemble the machine into its final form and an electrician plugs in the switchboard.

Testing and debugging the machine

At the end of the process, we imprint life onto the machine through the PLC programmer. It builds a control programme for it and tunes its functions. Thanks to the fact that we can handle all these activities, including final testing, in our workshop, you can be sure that there will be no hiccup during live operation and production will run like clockwork.

Want to know more?

Do you have any additional questions or do you already know for sure that you need a single-purpose machine? That’s great news! Just get in touch and we’ll take care of everything else.