Products

We design products to always meet specific customer needs. We produce first-class single-purpose machines, tools, jigs, and stamped parts to help improve your efficiency, quality, and competitiveness.

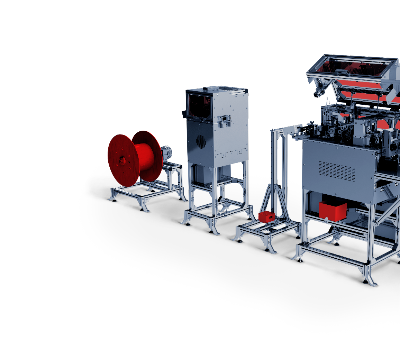

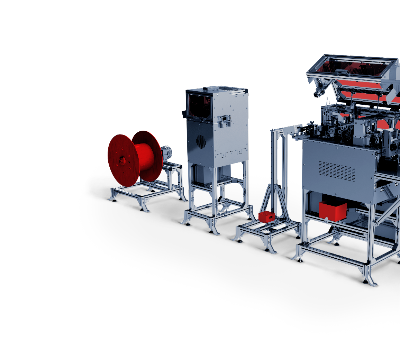

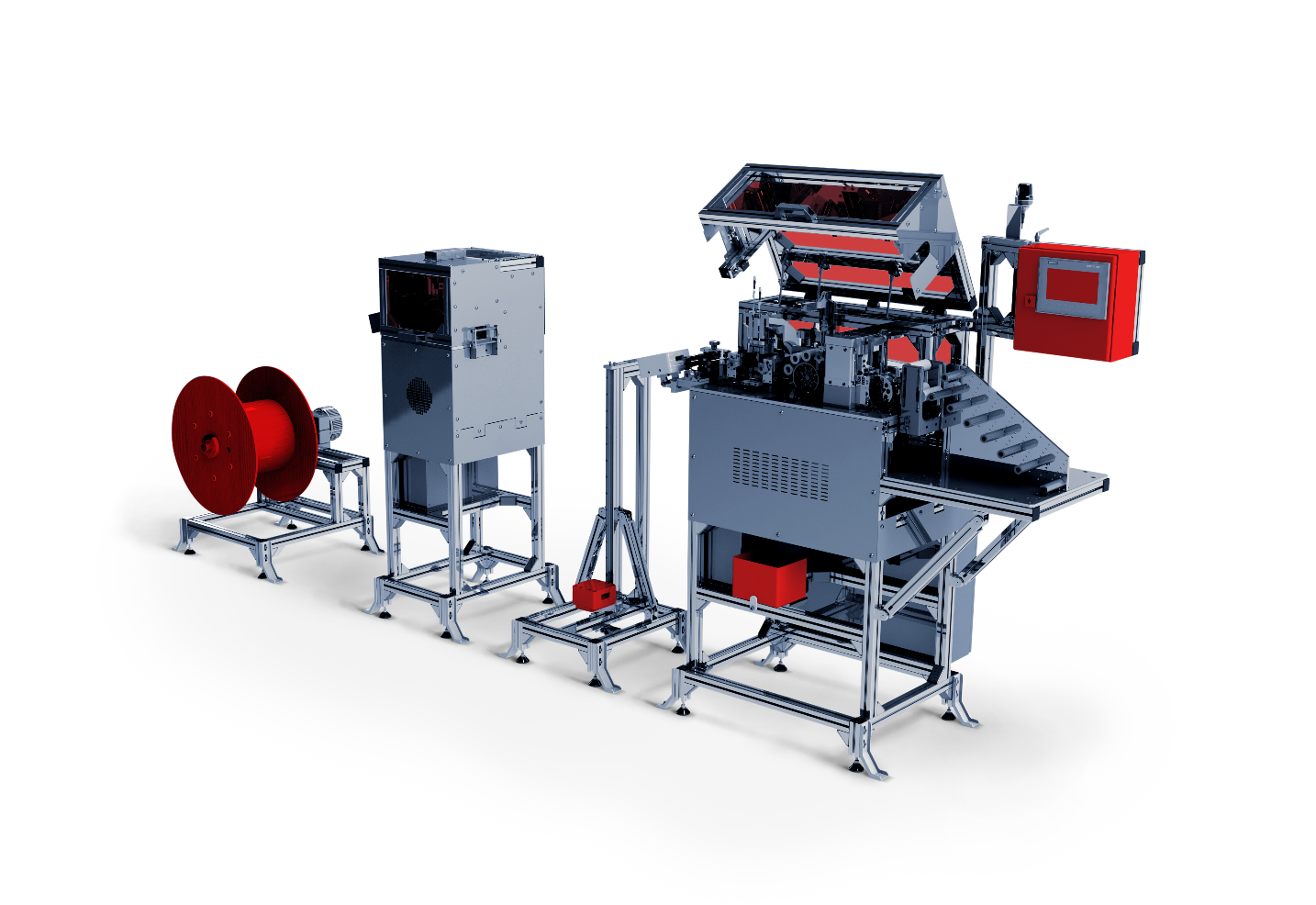

Single-purpose machines

become reliable partners in larger series production. While they have a limited range of functions, they handle their task quickly and accurately like no other. Just tell us your idea and we’ll turn it into a machine that will serve you well for a long time to come.

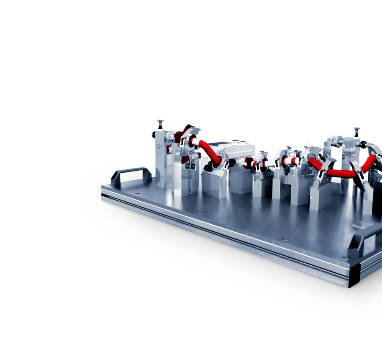

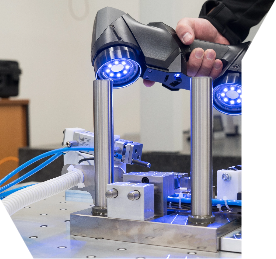

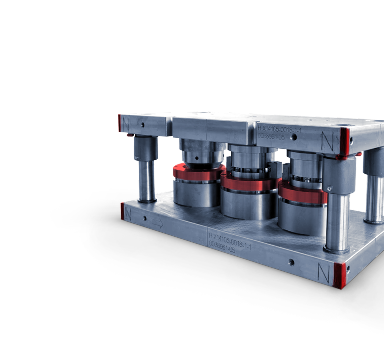

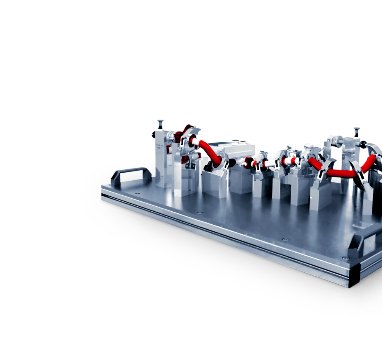

Jigs

are the most accurate quality controllers – they don’t take bribes and they’ve no room for imperfection. They make it easy to verify that the product 100% conforms to the drawing documentation and help you with precision welding or assembly. Our experts will be at your disposal and produce the product exactly according to your wishes.

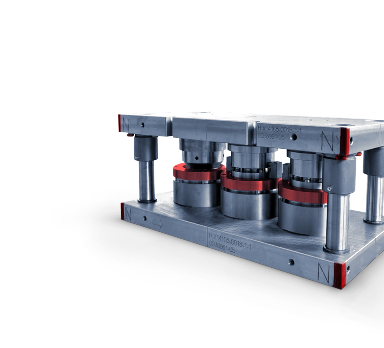

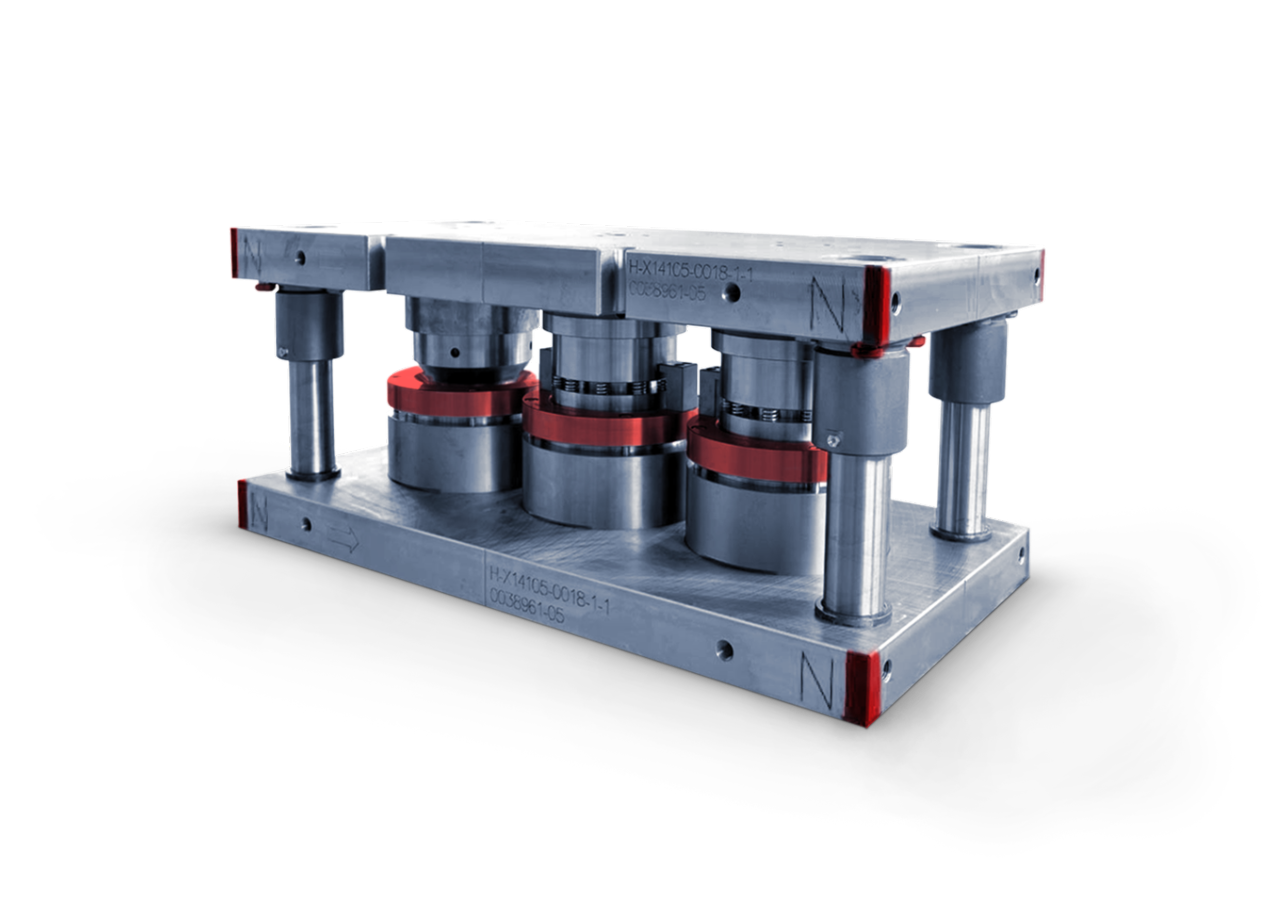

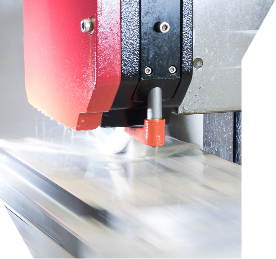

Stamped parts

are produced directly in our press shop, which still smells brand new. Whether you need 100 or 10,000 specific sheet metal parts, you can count on us. We can use a stamping tool you supply, or we can easily create one ourselves.

Production Process

Our technologies

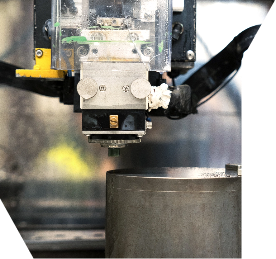

CNC milling

for machining steel of all grades, non-ferrous metal alloys, molybdenum, tungsten, and more.

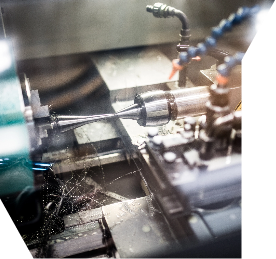

CNC turning

for machining steel of all grades, non-ferrous metal alloys, molybdenum, tungsten, and more.

We supply products for many industries

Automotive Industry

Electrical Industry

Construction Industry

Processing Industry

What can we do to help?

Over 30 years of experience gives us the confidence and you the assurance that we’ll find the best solution. We’ll do our best to ensure that at the end of the cooperation you take home the perfect product, tuned to the last detail, and also a grin from ear to ear. Just tell us your idea and we’ll take care of everything else.