Jigs

Jigs help you achieve absolute control and production accuracy. Inspection jigs check that the product is in order and that all requirements according to the drawing documentation are met. A welding jig ensures a perfect weld, an assembly jig facilitates the assembly of parts, and a measuring jig allows them to be measured accurately to the micrometre. We supply them primarily for the automotive industry, but we are happy to find solutions for other industries too.

Jigs help you achieve absolute control and production accuracy. Inspection jigs check that the product is in order and that all requirements according to the drawing documentation are met. A welding jig ensures a perfect weld, an assembly jig facilitates the assembly of parts, and a measuring jig allows them to be measured accurately to the micrometre. We supply them primarily for the automotive industry, but we are happy to find solutions for other industries too.

Jigs greatly facilitate the manufacturing process. They make it easy to identify defective parts, and instead of complaints, you’ll receive only complimentary emails from customers. We design them to minimise production time and effort and enable quick adjustments when switching between different parts and products. Get a powerful weapon to facilitate your quest for the best results and stay a few steps ahead of the competition.

What jigs can you choose from?

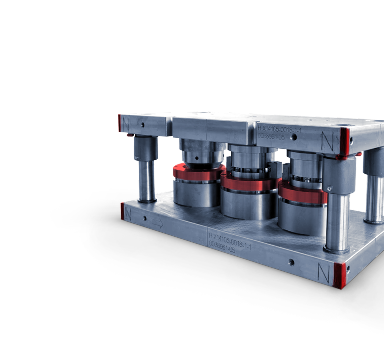

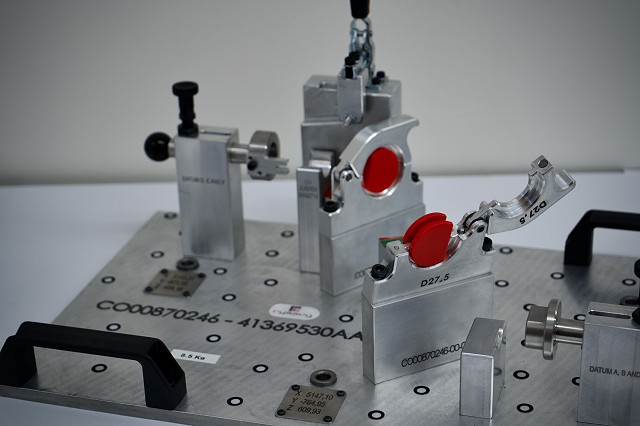

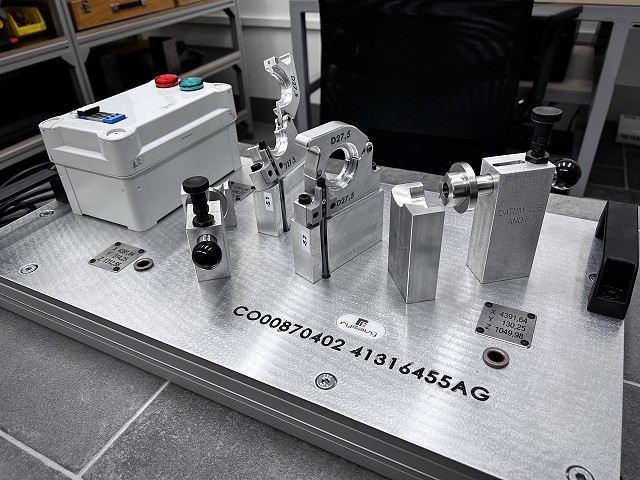

Measuring

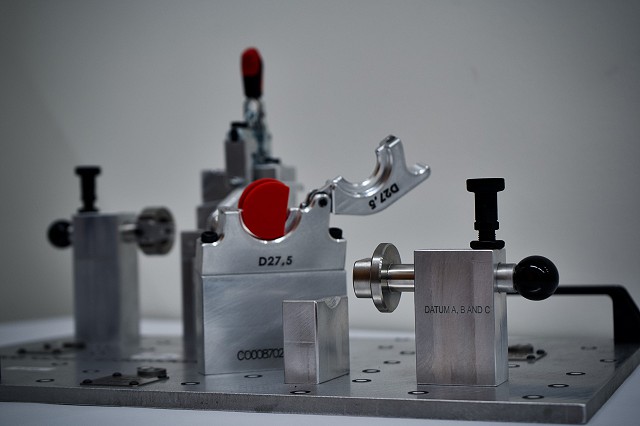

Allows you to accurately measure products to the micrometre. This enables you to quickly and reliably check that they meet the required specifications. You can easily eliminate defective pieces without them leaving for the customer.

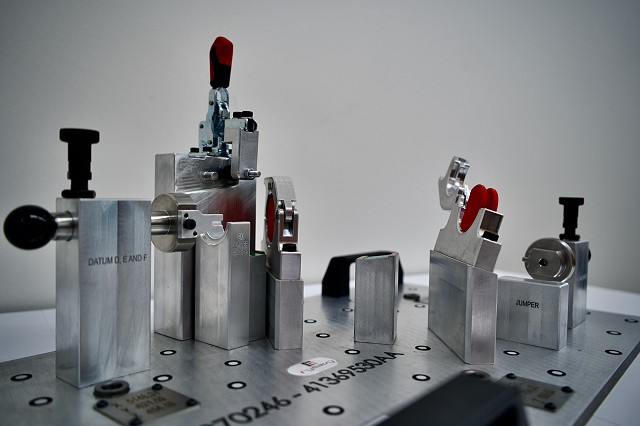

Inspection

They’ll help you directly check that each product meets all requirements according to the drawing documentation. They help you keep your production process under control and achieve consistent results.

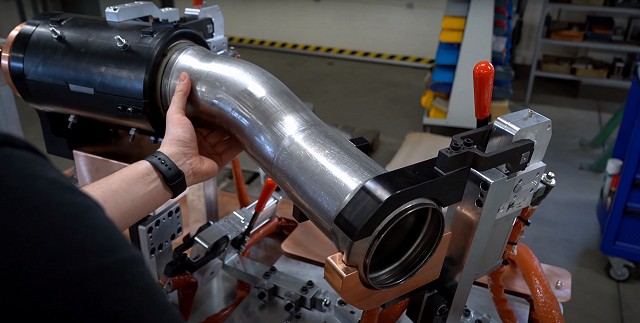

Assembly

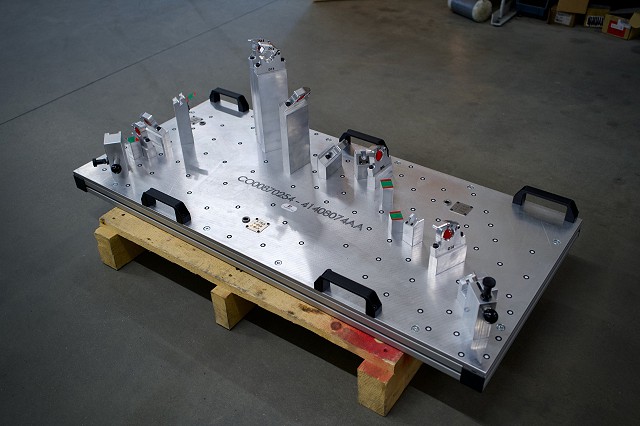

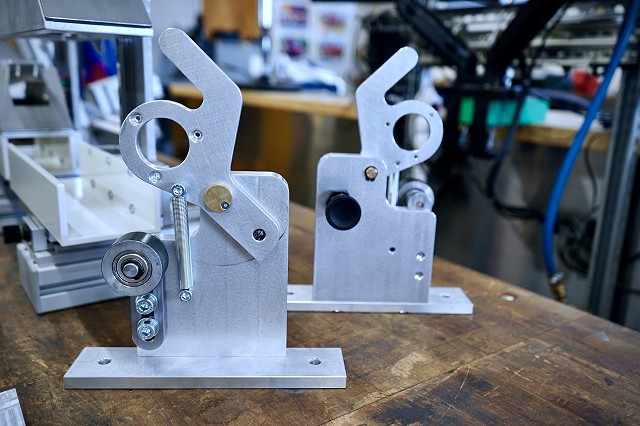

They enable, facilitate, refine, and/or speed up the assembly of the final product. They help you achieve a faster and more accurate assembly process, increase productivity, and minimise error rates.

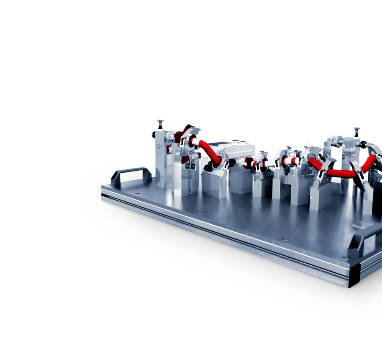

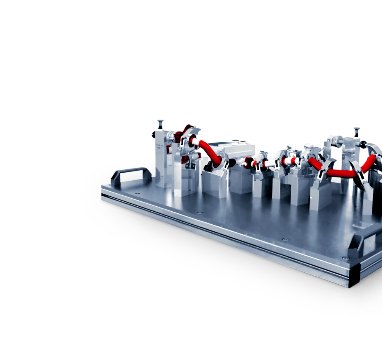

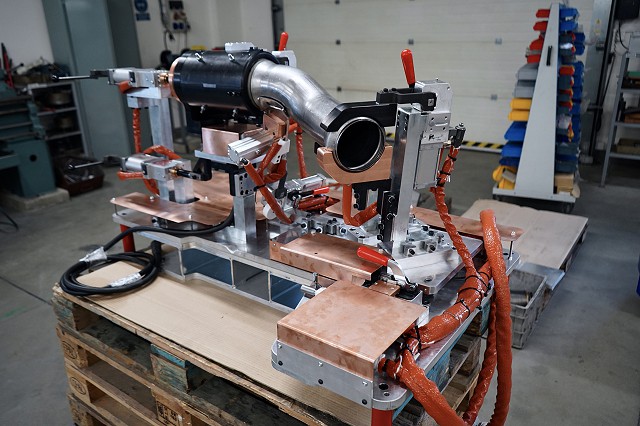

Welding

They enable, facilitate, refine, and/or accelerate product welding. They ease the welding process and ensure proper adjustment, resulting in fewer defects and a higher quality in the weld and final products.

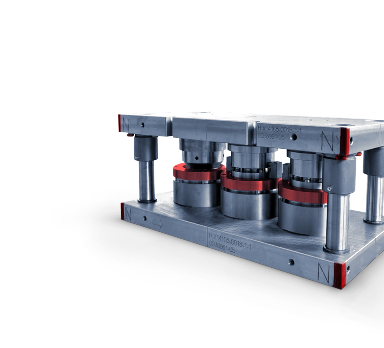

Machining

Used to clamp the product firmly and accurately into the machine tool. With their help, you can machine parts precisely and repeatedly. This will make production much faster and more accurate.

We supply products for many industries

Automotive Industry

Electrical Industry

Construction Industry

Processing Industry

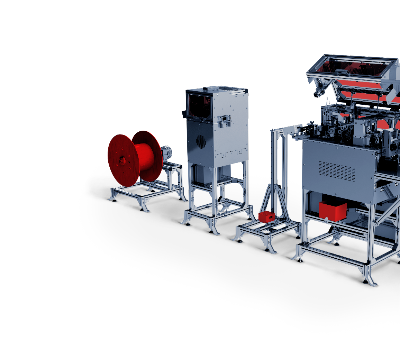

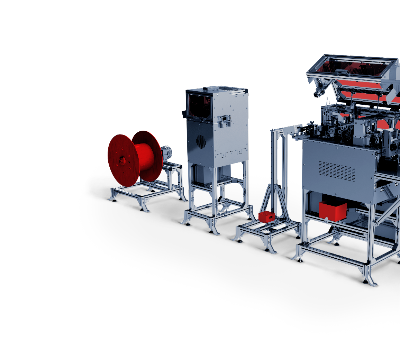

Production Process

Providing the necessary documents

To create a jig that exactly meets your expectations, we’ll need information to get started. We require CAD data, a PDF drawing of the product, and your internal standards. But if any of this is missing, you certainly don’t have to worry. We have a team of experienced engineers who can work wonders.

Creating a concept

Our seasoned designers create preliminary specifications, according to which we determine the final price. Once it’s approved, we go through all the documents. And because repetition is the mother of wisdom, we’ll re-examine the entire project. Nothing but a 100% result is acceptable for us.

Starting production

The drawing documentation travels a few doors down, where experienced technologists take charge. They determine the optimal technological procedure and order the necessary materials. Then they pass the baton to the production staff, who perform a symphony of CNC mills, lathes, and grinders. The conversations fall silent for a while, with only the sounds of cutting, milling, turning, grinding and wire cutting coming from the workshop. Once the noise stops, the parts go to the next station.

Checking everything carefully

Everything is manufactured, and this means that parts are assembled for an inspection measurement by the metrologist. The metrologist thoroughly verifies their quality, and if everything is in order we can go ahead and assemble.

Assembling the jig

A toolmaker enters the scene and, according to the drawing documentation, assembles the jig into its final form before the metrologist checks it once again.

Testing and debugging the jig

At the end of the process we verify its functionality and, if necessary, tune the jig to perfection. And then there’s nothing to stop it from heading to its new home, where it’ll run like clockwork thanks to careful controls and precision manufacturing.

Want to know more?

Do you have any additional questions or do you already know for sure that you need a jig? That’s great news! Just get in touch and we’ll take care of everything else.