Electrical discharge machining

Electrical discharge machining

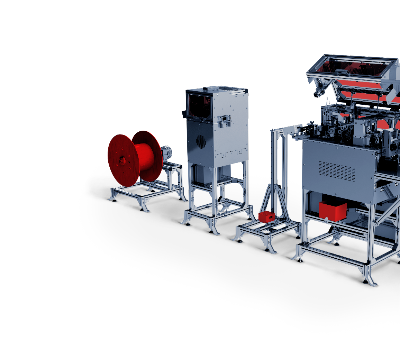

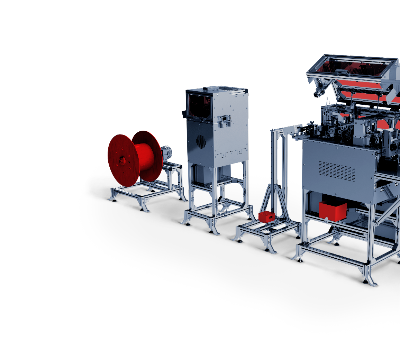

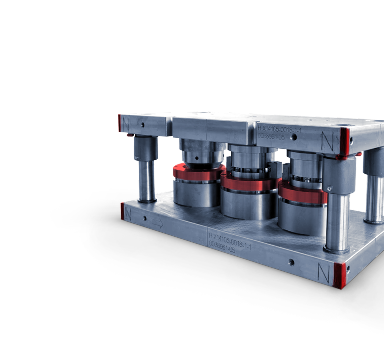

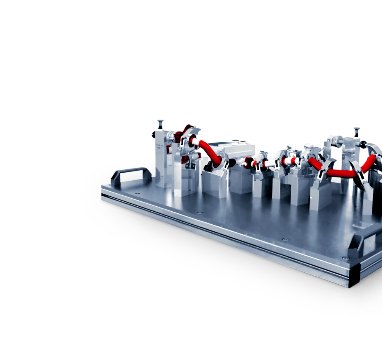

You want to get the highest quality products and we have the technology to achieve this with ease. EDM plays a key role in our manufacturing process and is one of the core technologies we use. We use it to machine all electrically conductive materials.

How does it work?

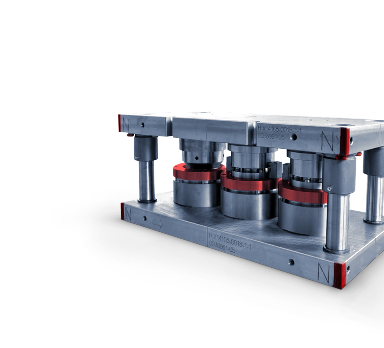

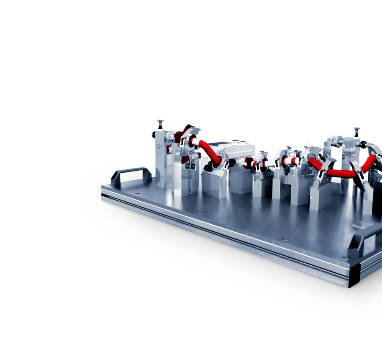

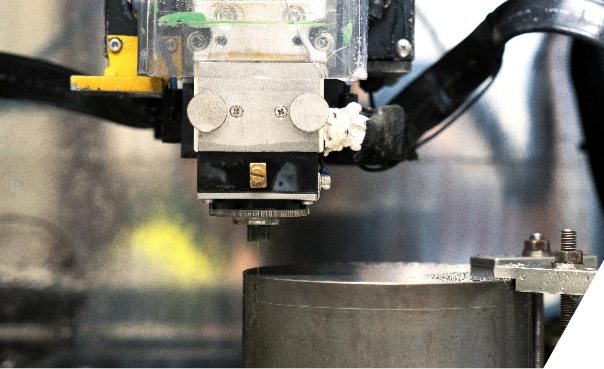

EDM allows us to achieve the precise and detailed machining of electrically conductive materials with the highest accuracy. It uses high-frequency electrical discharges between the electrode and the working material, creating small but very precise cuts. This makes it easy to produce a range of complex shapes and complex parts that would be difficult to create in other ways. And if you add our highly qualified employees, you can be sure that your projects are in the best hands.

What Machines Do We Use?

| Machine | Max. dimensions (travel) X/Y/Z [mm] |

|---|---|

| Makino DUO64 wire cutter | 650/400/420 |

| Makino EU64 wire cutter | 600/400/260 |

| Makino EU64 wire cutter | 600/400/260 |

| Wire cutter Makino DUO43 | 450/305/320 |

| Starting hole drill SY-3545 | 450/350/345 |

| CNC depth Penta GS433 | 400/300/300 |

What can we do to help?

Over 30 years of experience gives us the confidence and you the assurance that we’ll find the best solution. We’ll do our best to ensure that at the end of the cooperation you take home the perfect product, tuned to the last detail, and also a grin from ear to ear. Just tell us your idea and we’ll take care of everything else.